Austin Healey’s New Parts

Our Austin Healey 100 has had a brand new temperature gauge and sender as well as having the radiator reconditioned to solve the blockage and

Our Austin Healey 100 has had a brand new temperature gauge and sender as well as having the radiator reconditioned to solve the blockage and

We’ve now fitted a new radiator into our Austin Healey with hopes that this settles the running issues.

Here at Bridge Classic Cars, our Vehicle Technicians worked tirelessly up to the end of 2019 to get this gorgeous 1955 Austin Healey 100 home.

Dave has been working hard on our 1955 Austin Healey ahead of the owner seeing the car this weekend. It’s getting very near completion now.

The gearbox seals have been replaced of our 1955 Austin Healey. Now that it has been removed and fully rebuilt. The gearbox is now being

We are nearing completion on the restoration of our 1955 Austin Healey. Unfortunately, due to unforeseen circumstances the gearbox has once again been removed to

The original Austin Healey side screens have been stripped, cleaned and repainted. We have had to carry out some remedial repairs to the cracked frames

With our Austin Healey restoration nearing completion Dave has added the finishing touches to the beautiful engine bay.

Santa’s been and delivered our assortment of classic tyres ready to be fitted on our fantastic selection of classic vehicles. Santa of course being Graeme

The brand new boot lining has now been fitted out in the rear of our 1955 Austin Healey.

Exactly what the title suggest, we have now fitted the coil and washer bottle to our 1955 Austin Healey.

The brand new MWS 72 spoke stainless steel wheels have now been fitted to the 165 R15 tyres. As always, a huge thank to the

Having had our dials stripped, cleaned, repaired and rebuilt by our good friends at Speedy Cable in Swansea, Brian has been able to complete the

The brand new air ducting has now been fitted in our Austin Healey.

Brian has been working his magic on the refit of our 1955 Austin Healey. The re-assembly is progressing really well with freshly restored parts as

We are busy piecing together our new and newly refurbished parts as we continue to re-assemble our 1955 Austin Healey. The wing to bonnet trims

As we continue to work our way through the numerous parts that require refurbishment, here is the original steering wheel and horn push for our

Introducing EZ Power Steering Enjoy driving your classic car, but do you (or your partner) find the steering to be too heavy? Would you like

With a fresh new look our 1955 Austin Healey is out of the paint shop and now back in our assembly room as we start

Darren has now put our 1955 Austin Healey through the paint shop to give her a new and fresh look. The shell and loose body

Our Austin Healey 100M is now in final stages of primer. The shell has been coated in a red primer before being flattened down once

Darren is now perfecting the body of our 1955 Austin Healey, flattening down the primer and getting her ready for the new re-spray.

Our 1955 Austin Healey has now been coated in epoxy primer. We will now look to refit all of the panels to ensure the lines

It was a very time consuming and intricate task but Brian has now completed the polishing work on our original Austin Healey grille.

Our 1955 Austin Healey 100M engine is now complete and refitted. The body shell in now in for preparation ready for the respray to commence.

Next up for Brian is to strip, clean and polish our 1977 Austin Healey radiator. The top looks to have been hand painted at some

[vc_row][vc_column][vc_column_text]Our 1955 Austin Healey carbs have now undergone a full restoring rebuild. The manifold has been blasted and rumbled, they have been rebuilt using new

Moss Europe has delivered our brand new engine mounts in preparation for the engine refit which will commence early February.

We are now working on refurbishing the dash of our 1955 Austin Healey. The existing covering has been removed and the surface has been cleaned

Ady has now completed the rebuild of our 1955 Austin Healey 100M engine. We have replaced with a full set of gaskets throughout, refitted with

Our Austin Healey 100 has had a brand new temperature gauge and sender as well as having the radiator reconditioned to solve the blockage and leaking. We’re also fitting wing mirrors and need to adjust the handbrake.

We’ve now fitted a new radiator into our Austin Healey with hopes that this settles the running issues.

Here at Bridge Classic Cars, our Vehicle Technicians worked tirelessly up to the end of 2019 to get this gorgeous 1955 Austin Healey 100 home.

Dave has been working hard on our 1955 Austin Healey ahead of the owner seeing the car this weekend. It’s getting very near completion now. We can’t wait to see this gorgeous Healey back on the road after our recent restoration works.

The gearbox seals have been replaced of our 1955 Austin Healey. Now that it has been removed and fully rebuilt. The gearbox is now being re-married with the engine.

We are nearing completion on the restoration of our 1955 Austin Healey. Unfortunately, due to unforeseen circumstances the gearbox has once again been removed to be fully rebuilt. The gearbox was reported rebuilt sometime ago but the seals have possibly perished causing 3 or 4 leaks to appear, mainly around the overdrive.

The original Austin Healey side screens have been stripped, cleaned and repainted. We have had to carry out some remedial repairs to the cracked frames which involved welding new metal into the affected areas. The material and perspex which makes up the window have been cleaned down before rebuilding both sides ready for refit.

The hood cover has also been cleaned ready for install.

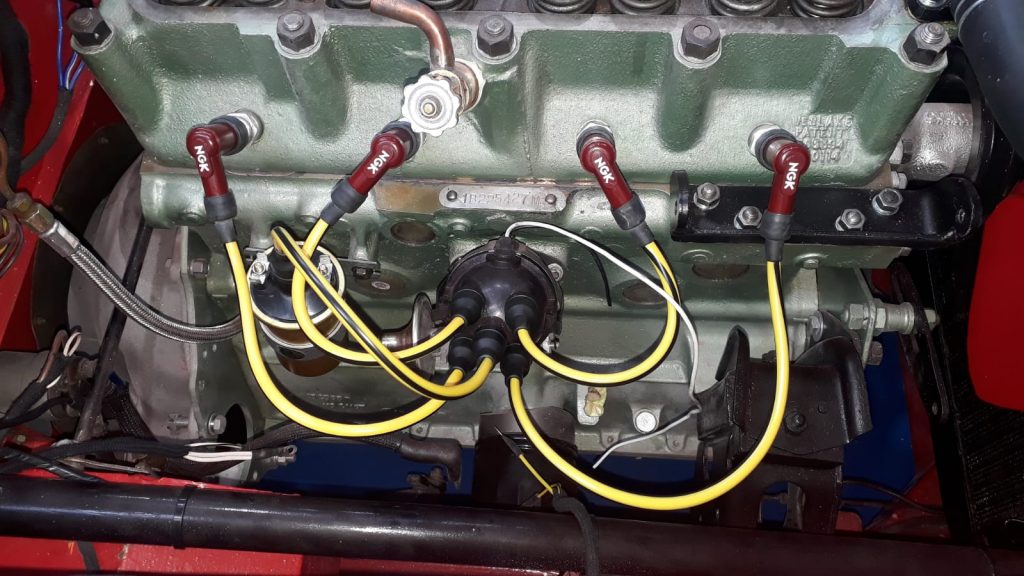

With our Austin Healey restoration nearing completion Dave has added the finishing touches to the beautiful engine bay.

Santa’s been and delivered our assortment of classic tyres ready to be fitted on our fantastic selection of classic vehicles.

Santa of course being Graeme from We Fit Any Tyres AnyWhere and the fantastic selection being: 1955 Austin Healey 100M, 1956 Ford Consul, 1959 Morris J, 1970 Mercedes 280SL Pagoda.

The brand new boot lining has now been fitted out in the rear of our 1955 Austin Healey.

Exactly what the title suggest, we have now fitted the coil and washer bottle to our 1955 Austin Healey.

The brand new MWS 72 spoke stainless steel wheels have now been fitted to the 165 R15 tyres. As always, a huge thank to the guys at WeFitAnyTyresAnywhere, you never let us down.

MWS Full Stainless Steel wire wheels are manufactured using state of the art technology. Special processes were developed after long years of Research and Development in making these wheels. Full stainless steel wheels are made of superior Austenitic grade stainless steel that has excellent protection against corrosion.

The Stainless Steel rims and shells are polished to a superior natural finish in special purpose machines. The hand polishing by highly skilled craftsmen compliments this.

The Stainless Steel spokes and nipples are electro polished to match the lustre and colour of the rims and shells.

The Wheels are specially treated as a final process to retain the lustre and colour.

100% inspection on finish on all the parts ensures only the best quality products are passed out.

Having had our dials stripped, cleaned, repaired and rebuilt by our good friends at Speedy Cable in Swansea, Brian has been able to complete the rebuild of our Austin Healey dash.

The dash itself was stripped and re-covered by us in house, the buttons have also been cleaned up here but we like to bring in the specialist skills of Speedy Cable for refurbishing dials as they always make such a beautiful job and have the tooling to make the job much easier.

The brand new air ducting has now been fitted in our Austin Healey.

Brian has been working his magic on the refit of our 1955 Austin Healey. The re-assembly is progressing really well with freshly restored parts as well as brand new parts all being fitted back up to the car. The horns are now back in position, the chrome work is gradually being secured and the metal edge finished panels are looking amazing.

We are busy piecing together our new and newly refurbished parts as we continue to re-assemble our 1955 Austin Healey.

The wing to bonnet trims are now in position, as is the front and back bumpers and badges. The fuel tank is also now secured.

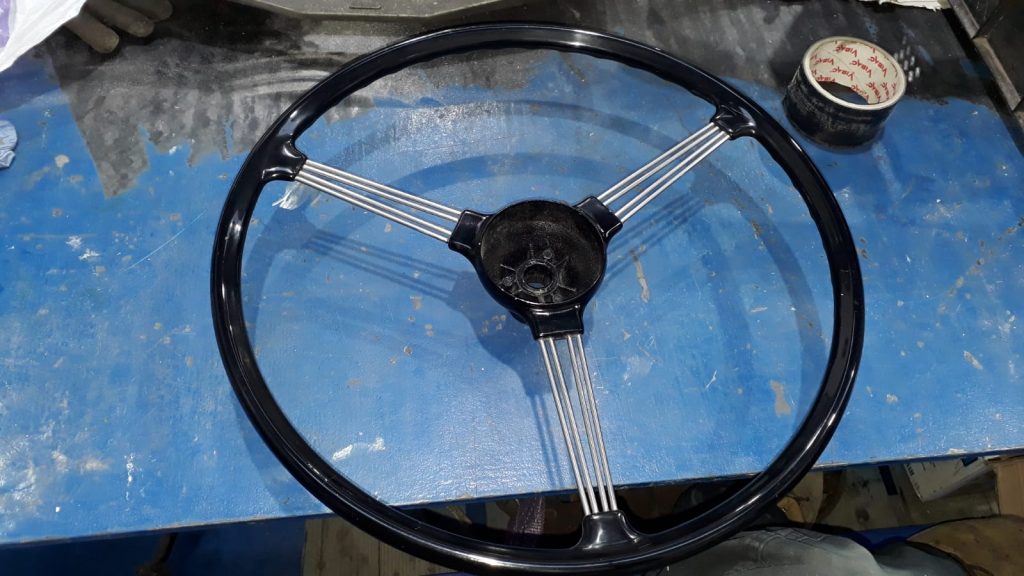

As we continue to work our way through the numerous parts that require refurbishment, here is the original steering wheel and horn push for our 1955 Austin Healey; cleaned and stored away for assembly.

Enjoy driving your classic car, but do you (or your partner) find the steering to be too heavy?

Would you like to cure this without changing the steering characteristics of the car? We can now offer you a solution: an EZ Electric Power Steering system that is completely hidden underneath the dashboard.

The existing steering rack or box remains unchanged and thus retains the standard steering ratio and setup. The amount of assistance is fully adjustable and is sensitive to speed and load. When we install the EZ system, we use CNC laser cut bespoke brackets designed to fit the original mounting points of your car. As no holes are drilled, with no cutting or welding to the chassis or body, the car can always be converted back to its original steering column. Under the bonnet there are no changes, everything remains as original. The advantages of an electrical system opposed to a hydraulic system are numerous. The electric motor only uses power when steering assistance is necessary whilst a hydraulic pump is continously operating when the engine is running. A hydraulic setup generally uses around 4 bhp and therefore consumes extra fuel, even when driving straight ahead.

Because the electric power steering system is truly speed sensitive, it will steer light at low speeds and not become lighter at high speed. The amount of assistance can be selected by turning a potentiometer, so that the driver can select the desired feel (i.e. more assistance with wider tires and/or a smaller sports steering wheel’. With a classic hydraulic system there is usually little feel and no possibility to adjust this at all.

In the unlikely event that the electric power steering system has a defect, the car would steer exactly like it did prior to power steering conversion. If a car fitted with an hydraulic system would have a fault the car would steer extremely heavy.

The EZ Electric Power Steering works without making a sound. It can not leak and is completely maintenance-free. When will you turn around with an EZ Power Steering conversion?

We have fitted the EZ Power Steering system to a number of our restorations now, including our recent 1960 Jensen 541S project. Our 1955 Austin Healey is now equipped with the new system and will make many many years of driving much more pleasurable for one very proud owner.

With a fresh new look our 1955 Austin Healey is out of the paint shop and now back in our assembly room as we start to fit back up the bright work, badges, exterior and interior components etc.

The new wheels, supplied to us from MWS are now in our possession but will not be fitted until nearing completion.

Darren has now put our 1955 Austin Healey through the paint shop to give her a new and fresh look. The shell and loose body panels are now looking stunning in vibrant red. We are now ready to progress with the next stage of the restoration which will be to refit.

Our Austin Healey 100M is now in final stages of primer. The shell has been coated in a red primer before being flattened down once more and guide coated. At this stage, all of the panels will be removed ready for final paint to begin.

Darren is now perfecting the body of our 1955 Austin Healey, flattening down the primer and getting her ready for the new re-spray.

Our 1955 Austin Healey has now been coated in epoxy primer. We will now look to refit all of the panels to ensure the lines and fit are as we want them to be ready to be prepared for paint.

It was a very time consuming and intricate task but Brian has now completed the polishing work on our original Austin Healey grille.

Our 1955 Austin Healey 100M engine is now complete and refitted.

The body shell in now in for preparation ready for the respray to commence.

Next up for Brian is to strip, clean and polish our 1977 Austin Healey radiator. The top looks to have been hand painted at some point in the past so we need to remove the paint before looking at options of polishing.

[vc_row][vc_column][vc_column_text]Our 1955 Austin Healey carbs have now undergone a full restoring rebuild.

The manifold has been blasted and rumbled, they have been rebuilt using new and refurbished parts. They have been set up and balanced and now they are ready to be fitted back up.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_gallery type=”image_grid” images=”25616,25615,25614,25613,25612,25611,25610,25609,25608,25607,25606,25605″][/vc_column][/vc_row]

Moss Europe has delivered our brand new engine mounts in preparation for the engine refit which will commence early February.

We are now working on refurbishing the dash of our 1955 Austin Healey. The existing covering has been removed and the surface has been cleaned up.

We have now re-covered the dash in brand new vinyl and high temperature auto adhesive.

Ady has now completed the rebuild of our 1955 Austin Healey 100M engine.

We have replaced with a full set of gaskets throughout, refitted with new studs, plugs, leads. The water pump and oil pump have been replaced, new cover assembly, piston assembly, pulley, big end bearing set, main bearing set and thrust washer set. The engine has been detailed in silver, black and the original green finish you would expect to see from new on the Austin Healey 100M. All of the nuts and bolts throughout have also been replaced with new to give the full set up a new and fresh look.

Bridge Classic Cars are award winning Classic Car Restoration and Maintenance specialists. Your pride and joy is in safe hands with our expert Classic Car Technicians. Take a look at our awards here.