Our E-Type Delivered

On Monday, Tony, Molly, and Nick delivered our 1968 Jaguar E-Type Series 1.5 Roadster to lucky winner Darcy. This is a beautiful classic and we

On Monday, Tony, Molly, and Nick delivered our 1968 Jaguar E-Type Series 1.5 Roadster to lucky winner Darcy. This is a beautiful classic and we

Before we deliver our stunning 1968 Jaguar E-Type Series 1.5 Roadster to its lucky new owner, Jonn has been doing its PDI. He was happy

Nick was on Suffolk Sounds radio talking about 1968 Jaguar E-Type Series 1.5 Roadster.

Our 1968 Jaguar E-Type Series 1.5 Roadster is now live on the Bridge Classic Cars Competitions website. When it comes to iconic symbols of classic

In the mid-1950’s, Jaguar had become one of the most successful racing teams of all time. With multiple wins at the fabled 24 hours of

The miles disappeared past the long-elegant bonnet of 77RW as the sun began to breach the horizon along a stretch of Autoroute on the 15th

When it comes to iconic symbols of classic cars, few vehicles can compare to the Jaguar E-Type. Unveiled in 1961, this masterpiece of design and

Classic car technician has been taking a look at our beautiful 1968 Jaguar E-Type Series 1.5 While working on the car he refitted the nearside

Tony recently picked up an old friend of ours, our 1968 Jaguar E-Type Series 1.5. It is now safely parked up in the workshop ready

After having rust repairs completed, our 1968 Jaguar E-Type Series 1.5 has had a thorough clean and is looking great! Parked in The Atelier with

Our 1968 Jaguar E-Type Series 1.5 has spent some time in the Bridge Classic Cars paintshop recently. Classic car technician Chris has been resolving a

After recently returning to the Bridge Classic Cars workshop, our 1968 Jaguar E-Type Series 1.5 has been under the care of classic car technician Scott.

Last night we said farewell to our 1968 Jaguar E-Type Series 1.5 after finishing its service. The final touches included tightening the steering rack, altering

With everything finished on our 1968 Jaguar E-Type roadster, there’s one last thing to do before we send it on its way. We found a

The rear axel has now been fitted back in our 1968 Jaguar E-Type Series 1.5. Mauro has been working to replace the seals and rebuild

Our lovely maroon 1968 Jaguar E-Type Series 1.5 is back in for a small dent repair and a check up. We’ve worked on this classic

We often get asked if it is possible for 2 people to go on a 2 week holiday, take everything they need, including the 2

Two tasks to carry out today on our 1968 Jaguar E-Type. First up we have the replacement of the split engine mounts. Thanks, as always

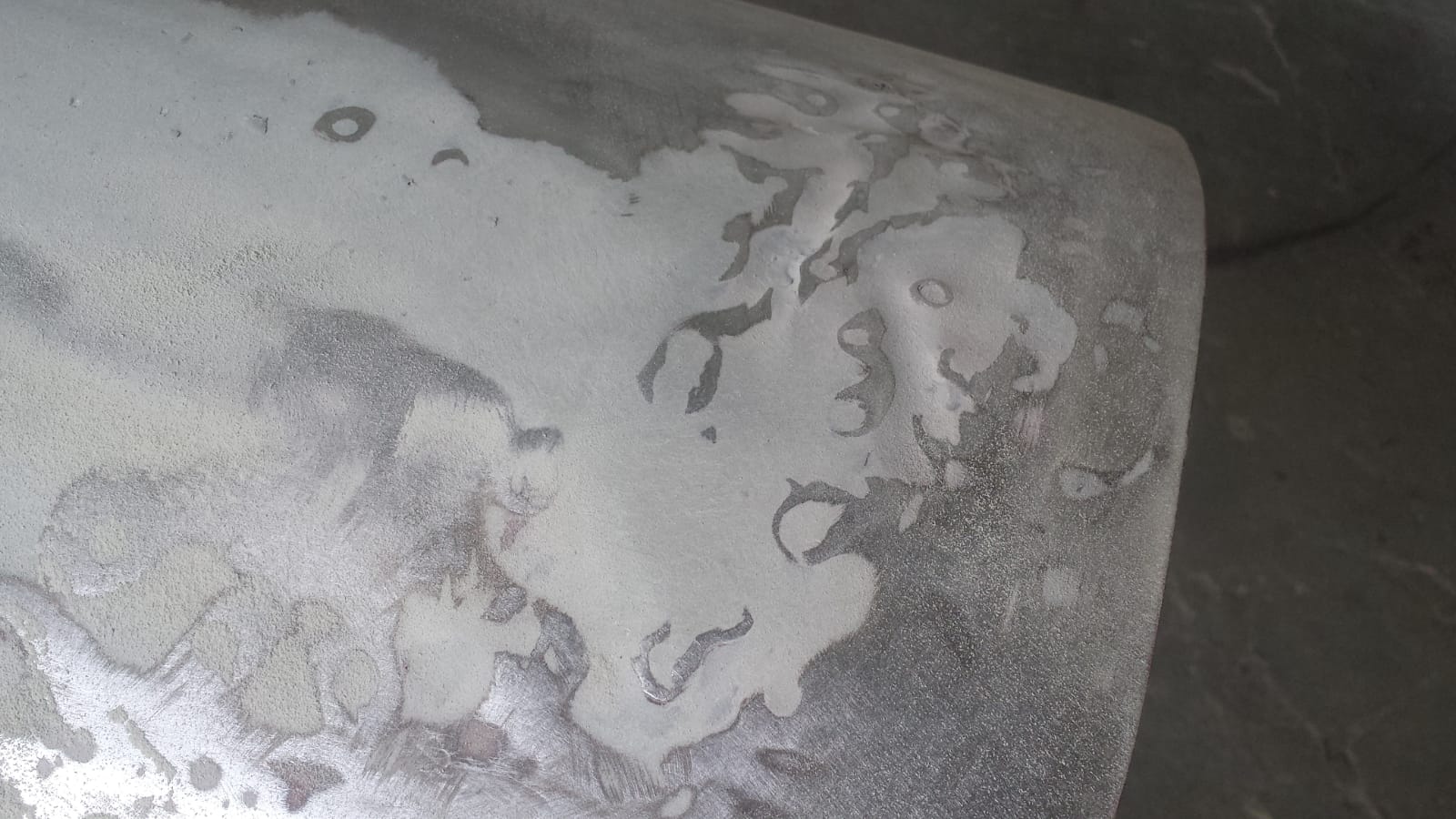

Our 1968 Jaguar E-Type has developed some issues with paintwork under the bonnet. Around the top of the engine the paintwork seems to be bubbling

We’ve seen some familiar faces this week paying us a visit to our Pettistree workshops. Our 1974 De Tomaso Pantera popped in to say hello…

Just as we thought our work was complete and the car can be returned we discover a slight leak coming from under the car. Upon

We have now had our brakes returned from the manufacturers Zeus Engineering having undergone an overhaul. Pete is currently fitting up so we can test

The repair work on our 1968 Jaguar E-Type is now complete. The chrome work and fittings were removed, we have repaired and re-shaped the door,

Whilst repairing the accident damage on our 1968 Jaguar E-Type Series 1.5 we have uncovered more areas in which we need to tackle to ensure we

It’s always a sad sight when you see somebody’s pride and joy accidentally damaged but none more so that our 1968 Jaguar E-Type Roadster. As

With the tasks now complete our 1968 Jaguar E-Type is back home and ready for the upcoming summer shows.

When purchasing new manifolds for the Jaguar E-Type they typically come already enamelled from the supplier, unless you opt for the more expensive option of

The paint preparation is well underway on our 1968 Jaguar E-Type roadster. We are looking to complete a full rear re-spray, including the doors, as

Back at the end of last year we had our 1968 Jaguar E-Type Series 1.5 in the workshops to inspect a brake binding issue. She’s

YMO 388F is a Series 1.5 Jaguar E-Type from 1968. In some ways this provides the best of both worlds. The looks of the original

On Monday, Tony, Molly, and Nick delivered our 1968 Jaguar E-Type Series 1.5 Roadster to lucky winner Darcy.

This is a beautiful classic and we all hope that Darcy enjoys it as much as we have.

Congratulations Darcy!

Before we deliver our stunning 1968 Jaguar E-Type Series 1.5 Roadster to its lucky new owner, Jonn has been doing its PDI.

He was happy with everything so fuelled it up and it is now ready to be delivered.

Nick was on Suffolk Sounds radio talking about 1968 Jaguar E-Type Series 1.5 Roadster.

Our 1968 Jaguar E-Type Series 1.5 Roadster is now live on the Bridge Classic Cars Competitions website.

When it comes to iconic symbols of classic cars, few vehicles can compare to the Jaguar E-Type. Unveiled in 1961, this masterpiece of design and engineering has been the classic of choice for many collectors, enthusiasts, and petrolheads for decades.

Enter the draw here.

In the mid-1950’s, Jaguar had become one of the most successful racing teams of all time. With multiple wins at the fabled 24 hours of Le Mans and other races across the world, the manufacturer had gone from strength to strength both on track and on the forecourt.

With the accolades of the C-Type and D-Type safely committed to history, Jaguar began to look to the future. By 1956, the D-Type had begun to lose its competitive edge thanks to its rivals developing cars to bring the fight to the big cats. This sparked a conversation about what concept would take Jaguar into a new decade of not just design but engineering.

William Heynes, Jaguar’s famous chief engineer, would task the now legendary Malcolm Sayer to begin working on the replacement for the D-Type. He put together a small team to begin work on fleshing out a new idea for what the newest Jaguar would be, known as the Experimental Department. In a meeting from the 30th of January 1956, it was noted in the minutes the discussion of a ‘2 1/2 litre engine in a D-Type car. The engine to give 200hp at 7,500rpm and a top speed of 180mph’. This, was the first mention in writing of the D-Type’s sister.

Bob Blake, a master panel maker who worked inside of the experimental department, annotated his notes from the meeting in early 1956 that the car would have ‘an aluminium engine with lighter brakes and wheels and a new body to be 6” lower’. This wasn’t going to be a development of something existing but an all new project for the department.

Previous to this, the idea of a D-Type variant had been mentioned as noted by Workshop Superintendent Phil Weaver, who in an earlier internal memo relating to ‘Models for Le Mans’ and talked about a 3 1/2-litre production D-Type as well as the later mentioned 2 1/2-litre model. This meeting was to do with a rumor that the rules would be changing for the upcoming racing season were by only 2 1/2-litre cars would be permitted in all categories. Weaver wrote of this, ‘Two courses are open to us on this car – one is to design a prototype as small and light as is practically possible and run it purely for one season as a prototype only.’ Following up later in his notes with ‘It might be advisable to considering making the prototype car in such a manner that it would have at least limited demand (as a production model) in a better equipped version for purposes other than racing. In this case, the closed type body would seem to be the most satisfactory answer.’

Tom Jones, a Jaguar engineer who played a key role in the development of the C-Type and D-Type was given the task of producing the sister car to the D-Type. When he was given the job, William Heynes said that the car would be designated ‘E’ and must be ready for Le Mans in 1956 – giving the team just 6 months to develop and produce the prototype for the world famous race. The naming of the cars is an interesting point however. Beginning with the C-Type, its original name was the XK120 Competition but was shortened to its nickname of C-Type and because of its success, the next car would follow in sequence to be named D-Type which would continue on into the late 2010’s with the F-Type.

The designation of ‘E’ wasn’t just it being the letter which followed ‘D’ but also represented the experimental nature of the new project. At this point it is important to state, that ‘E’ was not for E-Type. Jones would rely on master designer and aerodynamicist Malcolm Sayer to pen the new car. With the bodywork being calculated mathematically to give the least amount of drag, the chassis and powertrain were developed by Jones’s Experimental Department.

Decades later, the famous Jaguar test driver Norman Dewis would say of the project at this point ‘what was being produced was a sort of hybrid of the D-Type. It was because the ‘the old man’ (referring to Sir William Lyons) wanted a very fast sports car that fit in with the Jaguar’s image. This model was a low-key prototype following on the D-Type’. Of this first iteration, there are no surviving photographs or any visual records of the all-aluminium car, but it is known to have been fitted with a 2.4-litre engine as well as carrying a very early independent rear suspension development package engineered by the great Bob Knight. Although the car would go into testing, it was found to not be up to scratch due to its hasty development time, so Jaguar would field 3 D-Types at Le Mans in 1956.

1956 however would be the last year that Jaguar intended to race as a factory team. Between 1945 and 1955, the companies growth was meteoric and its road cars like the XK120 and the legendary 6-cylinder XK engined cars (which had been built off the back of the firms racing pedigree) were taking up not only the companies finances to produce but also the workforce to keep up demand. Racing, just wasn’t as important anymore. Sir William Lyons would begin the expansion of the Jaguar road car range around this time with cars such as the Mark VII saloon cars to build up a larger portfolio in the market, including the development of Project Utah which would ultimately form the basis of the MkI and MkII. This expansion would also take up the time of the engineers and technicians needed to run a successful motorsport department so the decision was made to stop.

Then in 1957, there was a fire. The Browns Lane workshops would be severely damaged in February of 1957 with dozens of cars destroyed, including the remaining XK-SS cars (road converted D-Types) as well as causing severe delays to the other production cars while operations were reinstated. With this final blow dealt, Jaguar in any form of competition would now be down to individuals and privateers, but were given help by the engineers from the former Racing department.

So with the company out of competition on the race track as a factory team, and no intentions of building cars for clients, what would be next? How would Jaguar keep their name in the headlines and therefore the cars rolling off the assembly line? The answer would start with an E.

The Le Mans project may have not made it to the track but it didn’t stop being developed. The Experimental Department were still working on the project in late 1956 to try and get something out of it. While William Heynes sat at his draftsmans table, Tom Jones, Phil Weaver, Bob Blake and Derrick White would work on developing the chassis and the mechanical side of the project.

In December of 1956, Malcolm Sayer would have the revised body design for the new car. A small two-seat sports car that took inspiration from the D-Type but held more of an emphasis on the aerodynamic stability and airflow over the front of the car. In early 1957, these designs were handed over to master panel maker Bob Blake to bring to life. This car, chassis XK101, was dubbed E1A by the team for internal referencing – E for Experimental, 1 referred to its type number and A was for Alloy/Aluminium. This name would stick to all those involved and in memory of the darling older child, the D-Type, the new car was referred to as ‘E-Type’.

As opposed to the newly released XK150, the E1A would use an aluminium central monocoque tub with a non-removable alloy frame work to support its bodywork and the car would employ the use of front and rear subframes for the running gear. E1A would be fitted with a 120BHP 2.4-litre XK engine as a starter, being as how it was an engine that the Experimental Department had access to, and was allegedly the same engine used in the previous ‘lost prototype’. Because of its smaller height, this allowed for Sayer’s design to be smoother over the bonnet without the signature power bulge.

E1A was what many would refer to as a ‘parts bin special’ with nearly all of the components coming from either the racing stores or from the production car spares department. The only thing that was bespoke to the project was that Bob Knight independent rear suspension set up. The car would use two swingarms to carry the wheel hubs as the moved through their arch, while the differential would be housed inside of a steel cage in the centre of the body.

By May of 1957, E1A would begin testing in and around the Jaguar factory. With the break-in period complete, William Heynes would adorn E1A with a set of trade plates (164 WK if anyone is interested) and head out on some real world testing around Birmingham with the one-off prototype and headed for the nearest by-pass to rack up an impressive 25 miles on the car, but later that evening the mercurial figure head of Jaguar, Sir William Lyons, would take the keys to E1A and head out for his own shakedown run. After 9 miles, he returned back to the factory with the engineer Ted Brookes waiting to receive the car. Brookes would be the man responsible for testing E1A on a daily basis, and after a check over the car would complete several 50 mile circuits before it was transferred to the MIRA test track for chief test driver Norman Dewis to put the car through its paces.

Brookes had officially signed of E1A as complete on the 22nd of May 1957 and the car taken into the factory and painted Pastel Green (a colour designated mainly for the Jaguar prototypes) and two small lights were fitted to the car and registered as VKV752. The car would be driven to multiple places across the UK over the next few months, from jaunts to Wales with drivers such as Margaret Jennings to day trips for testing at Silverstone.

E1A would find itself at the MIRA test track for weeks at a time after this. In June of 1957, Dewis would be testing E1A around the banking at the test track and record an average speed of 110MPH and a top speed of 130MPH whilst working with Dunlop to develop the brake and tyre package for the car. With the results gained from the E1A programme, it was decided around this time by the board and the engineers that the car should go into production after more development work on the cars suspension, seeing this new step forward as a game changer for the company and allow them to step ahead of many other manufacturers as the company entered the 1960s.

Between 1957 and early 1958, the car had been fitted with a 3.0-litre variant of the XK engine, as appearing the ‘The Motor’ magazine article by Christopher Jennings MBE. The car had been lent to favourable press outlets to do with as they pleased as long as they were nice about Jaguar’s new baby.

Jennings had decided to really try out and push the car (his wife had been a great fan of the earlier SS cars before the outbreak of war), with famously egging on Sir William Lyons by saying that the fastest car to complete his test had been an Aston Martin. He suggested that he take the car to the Brecon Beacons in the Wales, between Brecon and Carmarthen to a section of road he knew well to see what potential the new car would have. Lyons took the bait, saying he could take the car on this trip if he would compare it directly to that Aston Martin and other high-performance cars of the day.

As he said in his writings ‘On Sunday morning soon after 7am in perfect conditions we made a 20 mile warm up run and then ‘had a go’ – the result was almost fantastic.’ The journalist averaged just over 70mph on the course and on a longer nearly 50 mile stretch, the car would average nearly 68 mph and beat the Aston Martin’s time. Jennings would finish his statement with a very dry… ‘At no time did we exceed 120 mph.’

With some sense of fortune telling, Jennings would use these words in his article – E1A had the ‘potential to be a world beater’.

Development of the E-Type wouldn’t be solely down to E1A. By this time, the team had created the first true E-Type prototype car to begin refining and expanding on the concepts proven by E1A. To this, E1A would be used for high-performance test and for that, Jaguar racing manager Lofty England would call upon the service of trusted racer and Jaguar dealer Mike Hawthorn.

Hawthorn would test the car thoroughly and push it harder than it had ever been pushed before. Writing a detail and extensive report to the team noting the cars driving characteristics, mechanical aptitude and even down to ergonomic suggestions to get the most out of the car. He wasn’t gentle with his report… From this the team actioned several changes to E1A and the official prototype car.

In November of 1958, a simple engineers report in E1A’s fail simply states ‘engine removed to investigate loss of oil pressure – crankcase fractured on for main bearing webs.’ The car later went back to MIRA for further testing in December of 1958, but was called off due to bad weather. This would spell the end of the E1A story, after the engine damage and the abandoned test session, along with the success of the other E-Type prototypes – E1A was broken up for parts with its body panels sold to a scrap yard.

This was the end of not just the car, but the spiritual connection from those Le Mans victory and dominance by the Jaguar Racing Team and now the sophisticated road cars – A project which would give birth to a car the great Enzo Ferrari would call ‘the most beautiful car in the world’. This project, would give the world the E-Type and we, as petrolheads, should thank it every day for that.

Nice factual historic story. It is important to repeat and publish this story about the birth of the E Type. The younger generations lack this type of information about how the car industry developed . Bravo!

The miles disappeared past the long-elegant bonnet of 77RW as the sun began to breach the horizon along a stretch of Autoroute on the 15th of March 1961. It had been a handful of hours since the car and its pilot had left the shores of England with a singular purpose – orders to complete a herculean drive from the Midlands to Geneva as quickly as possible.

The story however, begins the day before.

On the 14th of March, the Jaguar team had been testing their latest creation at the legendary MIRA test track. This creation had caused quite the stir in the press, with the car mentioned in whispers and rumour – the E-Type. At the hands of god-like test and racing driver Norman Dewis, the E-Type was being through its paces ahead of its full release. That car, was 77RW. An E-Type Roadster and the 3rd one to be built so far. It’s sister, 9600HP (the first car built) was nearly 800 miles away in the Swiss town of Geneva being shown to the press.

As Dewis ran 77RW through its paces and worked methodically with the team to record results and make adjustments to the brakes, the next part of the car scheduled to be developed. The day grew on. The repetition and routine only broken by a telephone call, with a message which would become one of the most famous in automotive folklore.

The track manager at MIRA walked across the track during the cars downtime at around 2 o’clock in the afternoon. He announced to the team that the factory had rang and that 77RW would need to be returned to Coventry without delay. This sense of urgency instilled in the track managers voice made Dewis jump in the car and head for home.

As 77RW and Dewis pulled up to the workshop, two important names in Jaguar history would hove into view. William Heynes and Bob Knight, a pair of engineers instrumental in the mechanical side of Jaguar’s dominance both of the road and on the track. As Dewis got out of the car and approached the factory team, his first question was ‘what’s going on?’. Unbeknownst to Dewis, the factory had received a fairly frantic phone call from Geneva.

At the same time as Dewis had been putting 77RW through its paces, Jaguar PR Manager Bob Berry had been given pre-show demonstrations to the press at the Geneva Motor Show. So much was the hype around the car, and so impressed were the media that Berry was struggling to cope with the amount of ride alongs that 9600HP was being asked to perform. With this, and with the thought of potential orders for the new car slipping away, Jaguar’s figurehead, Sir William Lyons, rang the factory and ordered that the other car be brought to Geneva.

That message was the urgent message that had been given to the MIRA track manager.

As 77RW was wheeled into the workshop to be checked over, the plan was laid out to Dewis. He would drive from Coventry to Dover, from there he would get the 10pm ferry to Ostend in Belgium and then onwards to Geneva with the car needing to arrive by 10am. Dewis agreed and said that he would come back later on and pick up the car, to which he was told ‘no, you’ll go as soon as its ready.’ With Dewis protesting gently that he hadn’t got any change of clothes or to let his wife know, but the team had a response to that. A member of the team had already informed Mrs Dewis of her husbands adventure and gone round to his house to pick up a bag which waited for him in his office inside of the development workshop.

As 77RW reversed out of the garage, the sun had already set. It was 7:45pm on the 14th of March 1961.

The team handed him a ticket for the 10pm ferry and a brown envelope with fuel money. Wait, Dewis thought. 10PM!? That drive was easily over 4 hours from Coventry to Dover, and it would have been for mere mortals but this was Norman Dewis and he was on a mission.

The green roadster roared through the villages and towns as it made its way southbound towards its overnight crossing. On that night in March of 1961, 77RW was probably the fastest machine in the UK as it soared towards the southern town of Dover as the car ate up the 200 mile leg. As the car pulled up to the port, Dewis checked his watch. It was 9:45pm… He had covered that ground in just 2 hours.

However, as he drove through the empty lines towards the boat he found that the gates to the ferry had been shut 10 minutes before, far before the ferry’s departure time of 10pm. As Dewis’s heart sank, a man with a torch walked past the car set against the cold spring air. ‘Is that the Ostend boat?’ Dewis asked this shadow, it responded with ‘you’re too late”. Dewis quickly fired back with ‘I need to be on it’, whilst he called out to the shadowy figure, the torch light worked its way across the Malcolm Sayer designed sports car’s bodywork, ‘What’s this then?’ said the figure to which Dewis retorted with some gravel in his voice that it was the new Jaguar E-Type. Before he could even finish his sentence, the voice cracked back with ‘THE ONE THAT LAUNCHED YESTERDAY?! IT’S ALL OVER THE NEWSPAPERS. HANG ON…’ The sound of a walkie-talkies static broke the situation, and with a simple and direct sentence that shadowy figure would set a legend in motion. ‘You’ve got to get this guy on. He’s got the new Jag’.

With that, the Ferry crew lowered the ramp and held the boat so that one man and a sports car could enter the history books.

As soon as the ramp lowered on the other side of the channel, the E-Type was heading south at speed.

Dewis and 77RW had 500 miles to cover through the night and there was no time to waste. Around Brussels, as the sun begun to burn off the early morning mist, the pace of the car and its pilot would increase, averaging around 80mph through the Black Forest. Every half an hour or so, Dewis would glance down at the roadmap which served as his companion on this mad dash to Switzerland. Throughout this entire endeavour, he only had to refuel the E-Type once. As the minutes ticked by, and the countdown grew shorter and shorter to the 10am deadline, the odometer on this historic E-Type grew larger.

The lane markers flashed by with the passing of the hands on the clock, as another day was breaking over the continent. And then, like a beacon in the distance, the end was in sight. Geneva.

The driver and car made their way through the streets of the town towards the final point. As 77RW rounded the final corner, there, looking at his watch was Sir William.

Dewis got out of the car as Sir William walked over to his test driver, the first words spoken to him were ‘Thought you’d do it, Dewis.’ A brief but poignant sentiment from a famously stoic man. Next to approach the tired and sore driver was the wonderful Lofty England, Jaguar’s Service and Race Manager, who had been timing the run from Coventry and working out the average speeds Dewis would need to achieve to even be in with a chance of making it in time.

With arms outstretched and a face filled with joy and adoration for his friend, Lofty England would say the words which would cement this story into the annuls of automotive history and solidify the legend of the Jaguar E-Type. ‘Well done Norman. Fantastic driving. We worked your speed out’ and as a final statement which showed that neither Dewis, Jaguar or the E-Type would ever be underestimated and its prowess as a GT car would pass into folklore ‘we never thought you’d make it!’

But, the job wasn’t over. Just as soon as Dewis had arrived with 77RW he was ordered to begin demonstrations right away, the hotel bed and the sweet release of slumber would have to wait for this heroic man. Those who got in the car with Dewis that day had no idea that the car and its driver had just gone on an adventure which sadly outlived them both but went on to root their names in the history books forever.

Jaguar had originally planned to make just 250 examples of the E-Type, but thanks to the work of Dewis, Sayer, England, Berry, Knight, Heynes and the Jaguar team, the car would go on to be in production for the next 14 years and sell over 72,000 examples of this beautiful sports car.

When it comes to iconic symbols of classic cars, few vehicles can compare to the Jaguar E-Type. Unveiled in 1961, this masterpiece of design and engineering has been the classic of choice for many collectors, enthusiasts, and petrolheads for decades.

Its blend of beauty, performance, and innovation not only set new standards throughout the automotive industry but also cemented the E-Type’s place as one of the most significant vehicles in automotive history.

The creation of the Jaguar E-Type can be traced back to its predecessors, most notably of which, was the Jaguar D-Type, a Le Mans-winning race car. The E-Type’s creation was guided by the vision of Malcolm Sayer, an aerodynamicist who applied his expertise to craft the car’s distinctive shape.

Meanwhile, Sir William Lyons, the founder of Jaguar, oversaw the project, ensuring that the final product not only excelled in performance but also in aesthetics. The combination of Sayer’s aerodynamic design and Lyons’s attention to detail resulted in a car that was as fast as it was beautiful – a perfect example of the innovation that Jaguar has become known for.

The Jaguar E-Type made its grand debut at the Geneva Motor Show in 1961 and it caught the attention of the entire automotive world!

The Jaguar E-Type is known for its stunning aesthetics. From its long bonnet, sleek lines, and distinctive shape, even Enzo Ferrari himself is rumoured to have called it “The most beautiful car ever made.”

However, beyond its beauty, the E-Type was an engineering masterclass too. It featured a monocoque construction, a rarity at the time, which contributed to its strength and lightweight structure. Under the bonnet, the E-Type was fitted with a powerful XK engine, initially a 3.8-litre inline-six, which was later expanded to 4.2 litres.

The E-Type’s independent rear suspension was another groundbreaking feature, enhancing its handling and ride quality, and setting a new standard for sports cars.

Over its production span, the Jaguar E-Type evolved through three main series.

The Series 1 (1961 to 1968) is often considered the most desirable for its purity of design and performance. It featured glass-covered headlights, a smaller grill, and toggle switches on the dashboard.

The Series 1.5 (1968-1971) introduced several changes for improved safety and comfort, like open headlights, a larger grill, and improved cooling.

Lastly, the Series 3 (1971-1975) brought some big changes with the introduction of a 5.3-litre V12 engine. This offered a new level of performance and smoothness to go along with changes like a larger grille and revised bumpers.

The production of the Jaguar E-Type came to an end in 1975, but its legacy certainly continued way beyond that.

Today, the Jaguar E-Type holds a highly sought-after spot in the classic car market. Some examples, especially those from the early Series 1 production, are valued and sell for 6-figure prices at auctions and are considered a premium edition to any collection.

The Jaguar E-Type is an icon in the classic car world and, as it has its 63rd birthday on 15th March this year, I hope that it is celebrated as much as it deserves to be.

First saw the E Type in Moss,s Garage Luton just after launch.. I worked at Vauxhall just around the corner(Sales Dept) and I used to spend my whole lunch hour at this dealership just looking and admiring.( I had a Mk.V11 at the time which of course had the XK engine. I just couldn’t get over the beauty of the car although I was aware of it,s D Type heritage, this fixed head in silver blue was in my opinion the most beautiful and awesome car ever produced.This was 1961 and having been in the motor industry for 42 years have never been so impressed by any car launch since.

I saw my first E when I was 6 years old in 1967. It was being driven down East Grinstead High Street. It was an incredible sight because only superstars and famous footballers drove them.

Ever since then the E has been my ultimate dream car.

I had a 1966 4.2 coup from 72 -75 then 78-84 had a 67 XKE roadster..learned allot. Best car ever owned. Yes, a little nose heavy and yes it does over heat real easy but on the road driving no car is better.

Classic car technician has been taking a look at our beautiful 1968 Jaguar E-Type Series 1.5

While working on the car he refitted the nearside front bumper trim and swapped the spare wheel with the offside rear and knocked it up tight. He then cleaned and reglued the boot seal.

Jonn also tightened the nearside rear front shock absorber top bolt before checking all fluid levels (these were fine).

He went on to fit new exhaust nuts to the downpipe flange. After adjusting the washer jets, Jonn fitted O rings to the bonnet rear grille and secured them.

The road test of our E-Type went very well and Jonn was happy with the result.

Tony recently picked up an old friend of ours, our 1968 Jaguar E-Type Series 1.5.

It is now safely parked up in the workshop ready for the team to look at.

After having rust repairs completed, our 1968 Jaguar E-Type Series 1.5 has had a thorough clean and is looking great!

Parked in The Atelier with a range of other impressive-looking classic cars, it certainly is an eye-catching vehicle.

Our E-Type has been in the Bridge Classic Cars workshop several times over the years and we always enjoy welcoming it back, and we look forward to seeing it back out on the road very soon.

Our 1968 Jaguar E-Type Series 1.5 has spent some time in the Bridge Classic Cars paintshop recently.

Classic car technician Chris has been resolving a rust issue on the rear of this classic car.

After Chris had finished his work on our E-type, you can see from the pictures below that the car now looks much better and the rear appears to be free from rust.

After recently returning to the Bridge Classic Cars workshop, our 1968 Jaguar E-Type Series 1.5 has been under the care of classic car technician Scott.

Scott fitted new rear radius arms as the old bushes were shot. He also fitted new steering rack boots as the old ones had dried out and cracked. Scott went on to put the rear axle back together before stripping out the boot area and draining the fuel tank.

Once the tank had been drained and removed, Scott had better access to be able to assess the rust in the rear panel of the car.

After the rust has been assessed, the workshop team will also be investigating an issue with the front lights.

Our 1968 Jaguar E-Type Series 1.5 is a great-looking car and work will continue to get it back to its owner very soon.

Last night we said farewell to our 1968 Jaguar E-Type Series 1.5 after finishing its service. The final touches included tightening the steering rack, altering the high beams as their connection was poor, and finally, we cleaned it down.

One of the other final touches for this Jag before it left our workshop was to replace the diaphragm, which was making a strange whistling sound. Although this was a brand new element, we refitted it to ensure that the whistling stopped.

With everything finished on our 1968 Jaguar E-Type roadster, there’s one last thing to do before we send it on its way. We found a leak in the sump which needs a new helicoil.

Mauro has also replaced the rocker cover and the brake hose pipe.

The rear axel has now been fitted back in our 1968 Jaguar E-Type Series 1.5. Mauro has been working to replace the seals and rebuild the rear axel so that it doesn’t cause any more issues.

Our lovely maroon 1968 Jaguar E-Type Series 1.5 is back in for a small dent repair and a check up. We’ve worked on this classic in the past so its nice to have it back in for a freshen up. Mauro has discovered a rear differential leak in the rear axel so he’s taken its apart, stripped and cleaned it and will then replace the seal before re-building it all again and fitting it back into the E-Type.

Unfortunately our lovely E-Type had gained a small dent in its rear quarter panel. Chris and Matt have been correcting this by filling the dent, applying epoxy and primer before then repainting and polishing it so it looks brand new.

By the time Chris and Matt were done with the rear quarter, you would never know there had been a dent there. Good as new!

We often get asked if it is possible for 2 people to go on a 2 week holiday, take everything they need, including the 2 person inflatable kayak, all in a jaguar E-Type Roadster…and as we always say, ‘yes it is’…

Two tasks to carry out today on our 1968 Jaguar E-Type. First up we have the replacement of the split engine mounts.

Thanks, as always to Pete and the team at SNG Barratt for the quick turn around on new mounts. Arrived next day to our workshops and ready to be fitted.

We have now prepared the under side for the under seal application. The area has been cleaned up, the components that we need to avoid with our under seal have been masked up so we are ready to go.

Our 1968 Jaguar E-Type has developed some issues with paintwork under the bonnet. Around the top of the engine the paintwork seems to be bubbling which suggests a reaction occurring between the paint and the engine.

Our first thoughts steer us towards a possible engine temperature issue.

Upon closer inspection there are no visible temperature issues. We have adjusted the carburettors and tightened up a couple of the exhaust nuts but the temperature is reading perfectly.

It could be an issue with the original paintwork but we will continue to investigate all possible outcomes.

We’ve seen some familiar faces this week paying us a visit to our Pettistree workshops. Our 1974 De Tomaso Pantera popped in to say hello…

And our 1968 Jaguar E-Type returned to discuss a few little jobs he would like to see happen before the summer shows.

Just as we thought our work was complete and the car can be returned we discover a slight leak coming from under the car. Upon closer inspection we can see that the slave cylinder of our 1968 Jaguar E-Type has failed dropping oil onto the workshops floors but more importantly causing the brakes to work incorrectly.

We had a new slave cylinder on the shelf so this was a relatively quick fix and the car is now ready to go once more.

We have now had our brakes returned from the manufacturers Zeus Engineering having undergone an overhaul.

Pete is currently fitting up so we can test them and hopefully ahve some good news to report back to the owner with.

The repair work on our 1968 Jaguar E-Type is now complete.

The chrome work and fittings were removed, we have repaired and re-shaped the door, wing panel and lower bonnet. The body has been prepared and painted, blending in the quarter and scuttle.

Whilst repairing the accident damage on our 1968 Jaguar E-Type Series 1.5 we have uncovered more areas in which we need to tackle to ensure we complete the job to our very exacting standards.

With the body preparation now complete our E-Type is now waiting on paint to start which is due to begin at the beginning of next week.

It’s always a sad sight when you see somebody’s pride and joy accidentally damaged but none more so that our 1968 Jaguar E-Type Roadster. As you can see the nearside side (passanger’s) door was a little too close for comfort and the accident has mis-shaped the outer skin.

It has also clipped the front wing too.

Hopefully no further damage has been made internally but it will look to be a new outer skin, strip down before preparation and paint.

With the tasks now complete our 1968 Jaguar E-Type is back home and ready for the upcoming summer shows.

When purchasing new manifolds for the Jaguar E-Type they typically come already enamelled from the supplier, unless you opt for the more expensive option of stainless steel.

Our customer wished for us to purchase un-enamelled manifolds as he wanted to coat his with a heat proof alternative.

They are readily available without the enamel coating so we have sourced some and are ready to treated them.

There is a special procedure to applying the heat resistant paint with think layers having to be applied over a period of time and baked at 160’C.

The work has now been carried out and the results are fantastic.

The paint preparation is well underway on our 1968 Jaguar E-Type roadster.

We are looking to complete a full rear re-spray, including the doors, as well as tidying the bulkhead in the certain areas that would benefit from freshening up.

Back at the end of last year we had our 1968 Jaguar E-Type Series 1.5 in the workshops to inspect a brake binding issue. She’s now returned to have some touch up work carried out to the exterior paintwork.

The rear end will be painted and the engine bay around the bulkhead will be tidied.

YMO 388F is a Series 1.5 Jaguar E-Type from 1968.

In some ways this provides the best of both worlds. The looks of the original Series 1 car with some of the running gear improvements that came with the Series 2, as well as avoiding some of the price hike that attached to Series 1 cars.

Built as a left-hand drive car for the American market and first sold in Seattle, she returned to the UK via Holland in 2006 and was restored by Southern Classics with various upgrades including:

Coming to her current owner in May 2016, recent work has included carrying out a covered headlight conversion to restore Sayer’s original unpolluted design and a complete refurbishment of the bonnet revealing that it is the original, but has had at least a couple of punches on its nose over its lifetime!

In our Ipswich workshops today to investigate a brake binding issue and some intermittent electrical problems.

We’ve stripped the front brakes, freed up all the pistons, stripped down the offside front caliper and gave it a thorough clean.

We’ve upgraded the front flexi hoses to stainless steel, cleaned and greased the front pads.

We’ve checked and adjusted the front wheel alignment and all this has rectified the brake binding issues.

With regards to the electrical issues; the headlight switch was at fault so a new switch has been fitted along with a new fuse.

After a few minor adjustments the car is now ready to go back home.

Bridge Classic Cars are award winning Classic Car Restoration and Maintenance specialists. Your pride and joy is in safe hands with our expert Classic Car Technicians. Take a look at our awards here.

Leave a Reply